Dental laboratory

Anveli Dental, a global specialist in modern basal implantology, offers you dental treatment in modern dental clinics. Each dental clinic has specialists to treat the most complex cases.

Presentation of the dental prosthesis laboratory

AnveLAB is what we call an in situ laboratory. It uses digital technology to make dental prostheses. The measurements are taken by a 3D scanner, transferred to technicians, by modeling them by computer, the dental prosthesis is then shaped by a robot called CAD CAM. AnveLab is the most modern laboratory on the Balkan Peninsula since it is the only one to bring together 3D Scan-Print, CAD CAM and Press Ceramic equipment.

Equipment and technology of the dental prosthesis laboratory

The 3D intraoral scanner is the first step following preparatory dental care such as the placement of dental implants or the preparation of teeth that are to receive a veneer, crown or dental bridge. The latter makes it possible to replace the impression taking. The intraoral scanner is located in the dental office and is handled by the dentist or dental surgeon.

The 3D scanner is a piece of equipment in the dental prosthesis laboratory that can digitize and map an object in three dimensions. It will create a virtual image that will allow, via a special program, to create the design of future prostheses. It can be used to scan an impression, or a dental prosthesis previously made.

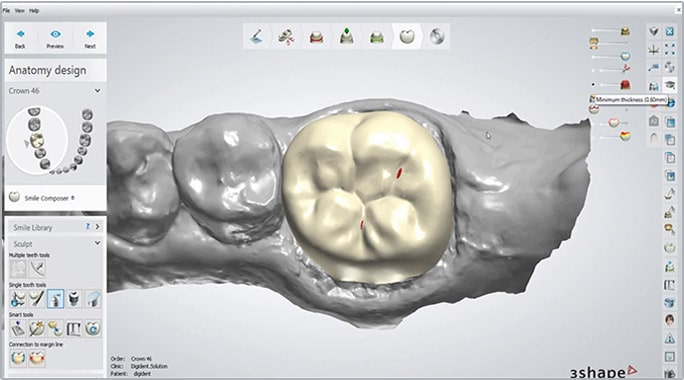

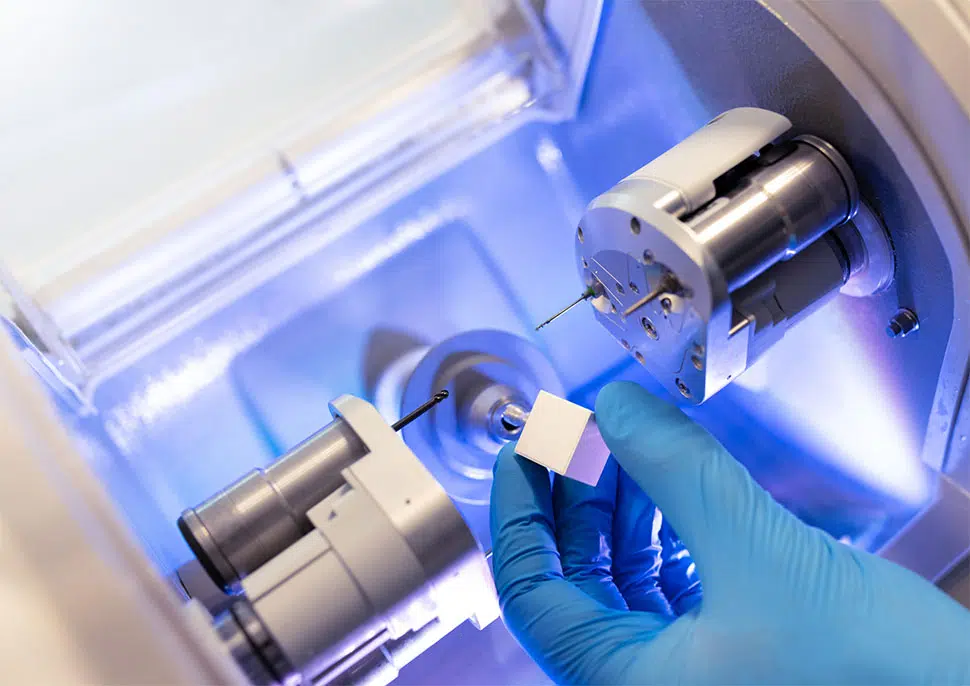

CAD CAM (computer-aided design & computer-aided manufacturing) CFAO in French (Computer-aided design and manufacturing). CAD / CAM programs are therefore used to produce dental prostheses using a computer . They allow great precision of execution. They are connected to a robot which manufactures the prostheses. The CAD / CAM program, whether 3shape or ExoCAD, makes it possible to visualize the dental prosthesis as if it were in the patient’s mouth.

AnveLAB uses the latest generation of CAD CAM (dental milling), the Roland DWX-52DCi. This little jewel of technology makes it possible to obtain dental prostheses, crowns, veneers and other inlays / onlays with great precision . Their design is carried out by computer using 3D design programs.

IPS e.max pressed ceramic is the most aesthetic material in dental prosthetics. It provides a perfectly natural finish. It is used for visible teeth since it is slightly less resistant than zirconia . It is obtained with a furnace containing a cylinder which presses the ceramic at the same time as it is melted. The ceramic obtained is then ultra hard and makes it possible to obtain a unique transparency effect.

Constitution de l’os maxillaire L’os de la mâchoire est constitué comme tous les os du...

Discover the fixed prosthesis on All on 4 or All on 6 implants: definition, advantages,...

Bone grafting and sinus lifts carry risks. It is essential for the dentist who performs...